Processing

Welding, gluing and laminating

Welding

Original material

Tubus honeycombs with open cells

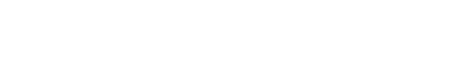

Welding cover layers and honeycomb mat

Tubus honeycombs can be welded using heat and pressure in a continuous or discontinuous process. This is possible with or without additional materials.

The materials to be welded are heated above their melting temperature and made liquid. As this occurs at various temperatures for different plastics, only plastics of the same kind or with similar melting indices can be welded with each other.

Sample process:

Laminating

Hot gluing

Hot pressing

Cover layers:

Ideally fibre-matrix semi-finished products with a thermoplastic matrix are used. Fibre-matrix semi-finished products are understood as materials made from reinforcement fibres that are drenched in a plastic matrix.

Sample cover layers:

Textiles based on polyolefins

Mats based on polyolefins

Fleeces

Fabric/cores based on polyolefins

Hybrid fabrics with a polyolefin element

Gluing

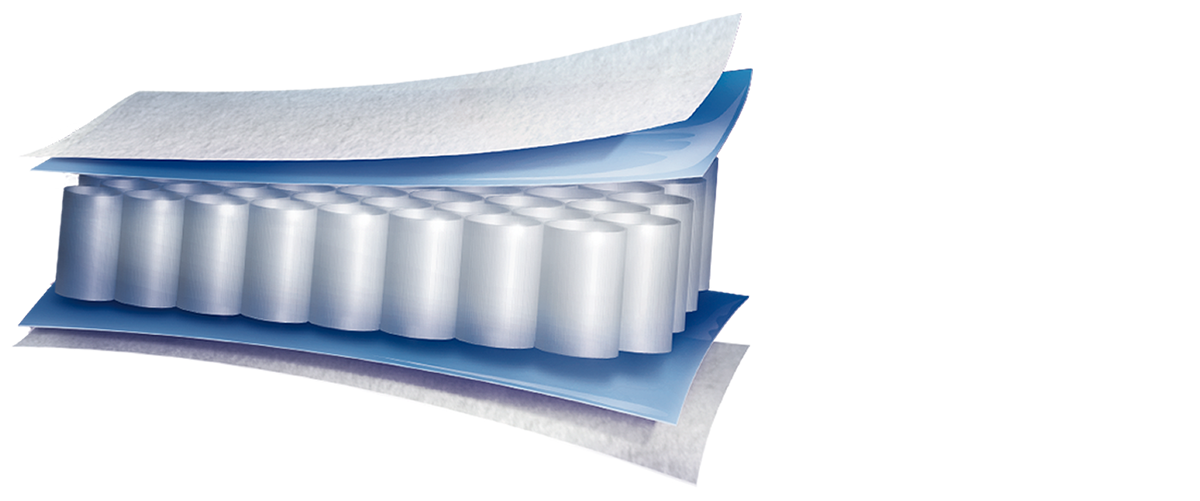

Original material

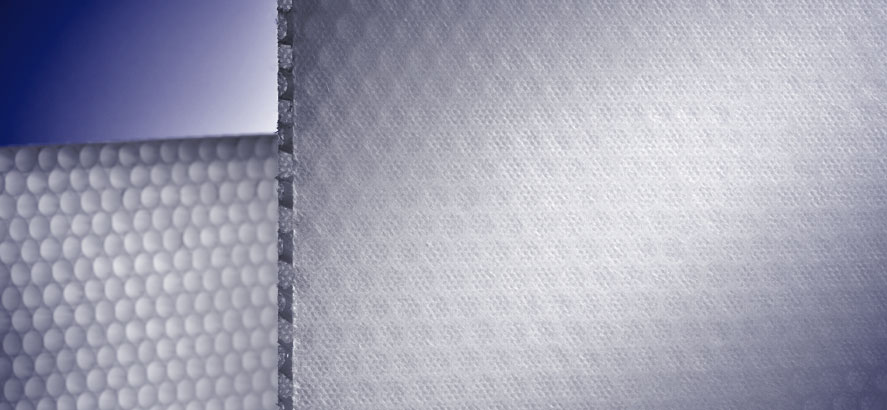

Tubus honeycombs with polyester fleece

Gluing cover layers and honeycomb mat

The selection of adhesives is made mainly due to the adhesion to the cover layer. The adhesion in the fleece is purely mechanical. Air pockets in the adhesive should be avoided because these massively reduce the stability values and may result in bubbles when heating the honeycomb plate, e.g. sun radiation.

Sample process:

Continuous and discontinuous processes

Hot, cold and vacuum presses

Sample adhesives:

1-K / 2-K polyurethane adhesive (PUR)

Hot melt adhesive

Reactive adhesive

Cover layers:

When gluing, the cover layers can be selected from thermoplastic, duroplastic or other materials.

Sample cover layers:

Fibreglass reinforced plastic (GRP)

Prepeg Fibreglass mats thermoplast (GMT)

Metal (e.g. aluminium, steel, stainless steel)

Wood, plywood, HPL, trim, stone

Anti-slip surface

Laminating

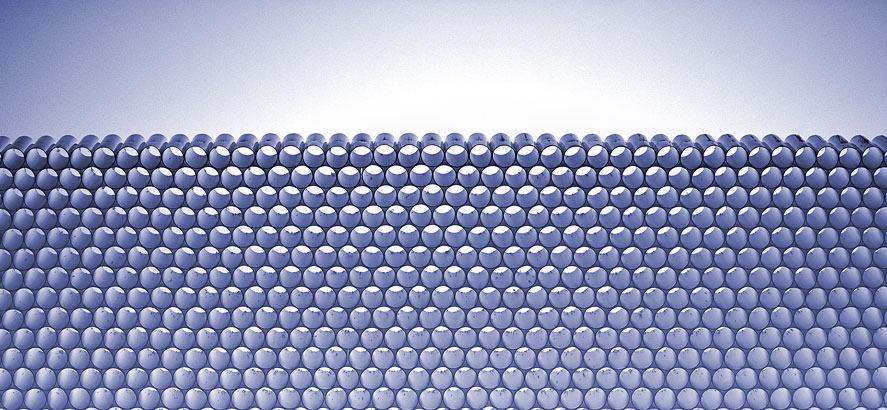

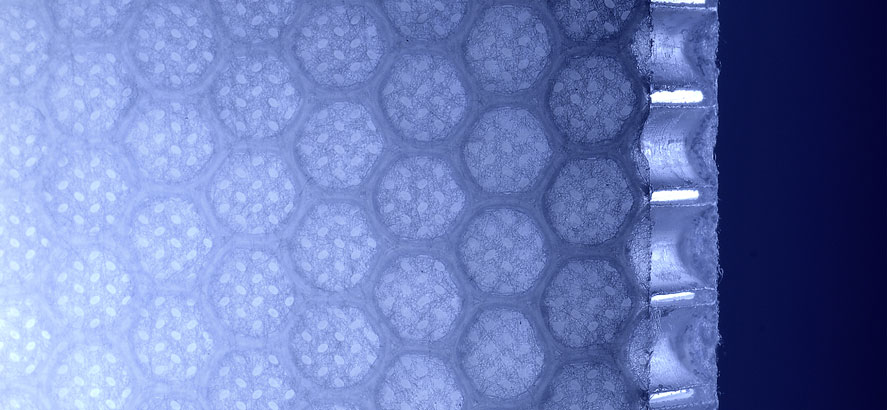

Original material

Tubus honeycombs with fleece cover layer

Laminate cover layers on the honeycomb mat

Tubus honeycombs can be processed into sandwich components and pressed parts using various lamination processes. The cover layers are embedded in a resin matrix and connected with the honeycomb mat.

Sample process:

Manual laying process (with vacuum presses)

Injection fibres

Vacuum infusion

Light-RTM

Sample resins:

Polyurethane resin

Polyester resin

Epoxy resin

Phenol resin

Cover layers

Various materials combinations are possible for the cover laminates and these must harmonise with the honeycomb core. In order to achieve the ideal result, an individual cover layer should be selected for each component.

Sample cover layers:

Fibreglass reinforced plastic (GRP)

Metal (e.g. aluminium, steel, stainless steel)

Wood, plywood, HPL, trim, stone

Anti-slip surface

Technical application instructions and recommendations are neither binding nor guaranteed. They match the current state of our knowledge and do not release the user of Tubus honeycombs from the responsibility of checking that the products are suitable for the proposed use.

Further information

Learn more here about the characteristics and processing options for our products:

Downloads

All technical data and specifications as well as processing information is found in our PDFs that can be downloaded: